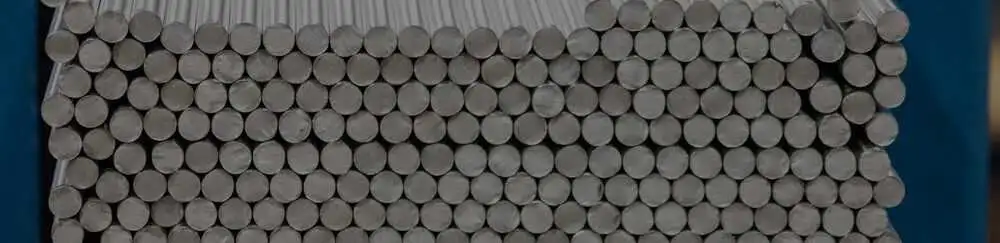

Specialty Nickel Alloy Bar Stock

Specialty Nickel Alloy Bar Stock

Specialty Nickel Alloy Precision Ground Bar Stock

Unmatched Performance in Extreme Environments

Specialty Nickel Alloy bar stock is best known for exceptional corrosion resistance and high-temperature strength. Alloys with higher nickel and chromium content offer superior resistance to oxidation and harsh chemicals, while those blended with iron or copper tend to improve machinability and reduce cost at the expense of some corrosion performance. Heavier than stainless steel and highly stable under thermal and mechanical stress, it is well-suited for critical applications in aerospace, and chemical processing environments.

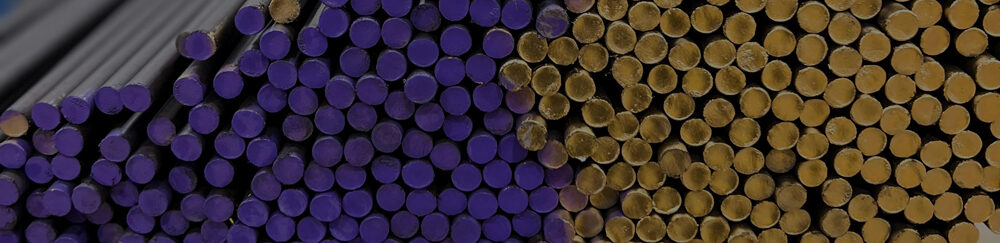

A Wide Range of Specialty Nickel Alloys

We understand that different applications demand specific material properties, which is why we stock and regularly centerless grind a comprehensive range of specialty nickel alloys, including:

Nickel-Based Superalloys:

- Monel

- Monel 400

- Inconel® (various grades)

- Hastelloy

- Waspaloy

- A286

- C-279

- Stellite 6B

Our knowledgeable team is well-versed in the unique characteristics of each alloy and can guide you in selecting the ideal material for your specific application. Whether you require the high-temperature strength of Inconel, the corrosion resistance of Hastelloy, or the versatility of Monel, we have the expertise to provide you with the perfect solution.

Specialty Nickel Alloy Bar Stock

Versatile Applications Across Industries

The exceptional properties of our precision ground specialty nickel alloy bar stock make them suitable for a wide range of components across various industries. Some of the common applications for our products include:

- Commercial aircraft components

- Oil and gas refinery operation equipment

- Chemical processing equipment

- Power generation and energy production components

- Pollution control and environmental systems

Our specialty nickel alloy bar stock is trusted by manufacturers worldwide to deliver reliable performance and consistent quality in critical applications where high strength, corrosion resistance, and chemical resistance are essential.

Why us

Why M&M Quality Grinding for Specialty Nickel Alloy Bar Stock

Unparalleled Precision and Quality

When you choose M&M Quality Grinding for your specialty nickel alloy precision ground bar stock needs, you can expect:

- Tighter Tolerances: State-of-the-art grinding equipment and skilled technicians ensure tight tolerances for high precision components.

- Superior Finishes: We offer a wide range of surface finishes starting at 6 RMS, giving you the flexibility necessary to achieve the perfect finish.

Increased Efficiency and Cost Savings

By using our precision ground specialty nickel alloy bar stock, you can optimize your machining operations and realize significant benefits, including:

- Increased Tool Life: The superior surface finish and straightness of our ground bar stock reduces vibration and wear on your cutting tools, extending their lifespan.

- Reduced Machine Wear: Our precision ground bar stock minimizes vibration and wear on your machines, leading to less downtime and longer machine life.

- Improved Productivity: With the consistent quality and straightness of our ground bar stock, you can boost your productivity with higher throughput and faster cycle times.

Contact M&M Quality Grinding

For questions, inquiries or concerns, reach out to our team today!

At M&M Quality Grinding, we provide our customers with the highest quality specialty nickel alloy precision ground bar stock and exceptional customer service. We take pride in building long-lasting relationships with our customers, and we are committed to being your trusted partner for all your precision ground bar stock needs.

M&M Quality Grinding

Contact us today to learn more about our specialty nickel alloy precision ground bar stock and how we can help you achieve your manufacturing goals.