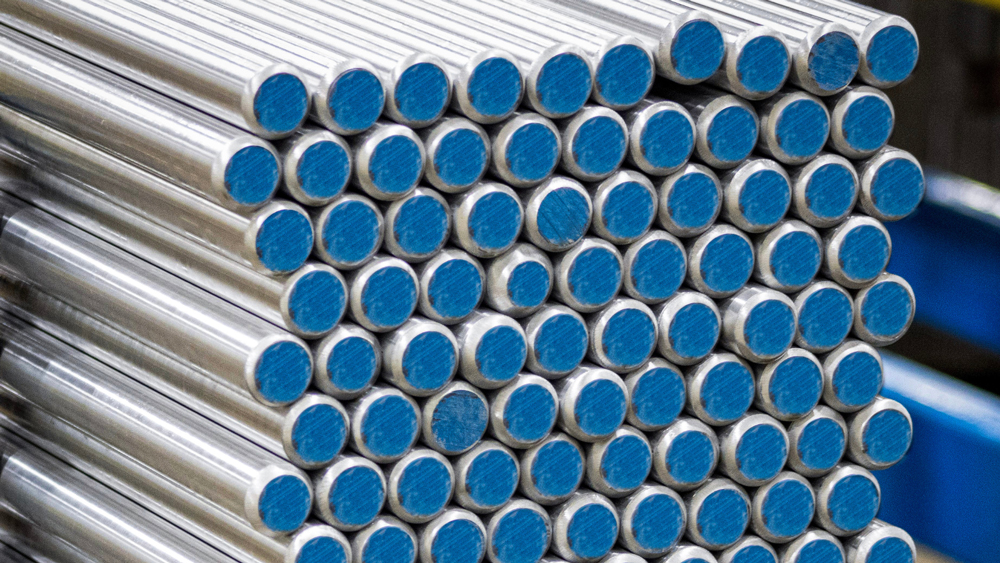

When it comes to precision machining, what goes into a part matters just as much as how it’s made. That’s why the first step in getting a high-quality finished product often starts with choosing the right bar stock.

At M&M Quality Grinding, we work with engineers, buyers, and machine shops every day to provide bar stock that’s not only ground to spec but also tailored to the needs of the final application. Below are a few key factors to consider when making your next purchase.

1. Material Type Affects Performance and Machinability

Carbon Steel

Cost-effective and easy to machine, carbon steel is a go-to for high-volume applications that don’t require extreme corrosion resistance. We regularly grind grades like 1018, 1045, and 1144.

Alloy Steel

Need more strength, toughness, or heat resistance? Alloy steels like 4140 and 4340 are commonly used in structural parts, power transmission, and high-stress environments.

Stainless Steel

Ideal for parts that need to resist corrosion or high heat. Common grades we grind include 303, 304, 17-4 and 316, each with its own benefits depending on weldability, machinability, or corrosion resistance.

Specialty Metals (Nickel Alloys, Titanium, etc.)

Used in aerospace, medical, and energy sectors, these materials demand precise grinding and handling to avoid surface damage and meet tight specs. We offer unique cells dedicated to aerospace, and medical applications.

2. Diameter Tolerance, Straightness, and Surface Finish All Play a Role

Buying “off-the-shelf” bar stock can create manufacturing challenges for example, Poor straightness can lead to misfeeds or vibration during machining. Additionally, oversized or inconsistent diameter adds to cycle time. At M&M, we grind bar stock to hold strict diameter tolerances and straightness specs that match your specific application needs.

3. Application Drives Specification

Are your parts going into hydraulic cylinders? Medical implants? Aerospace components? Knowing how the bar stock will be used allows us to guide you toward the right combination of material, diameter, and finish, especially when reliability, fatigue resistance, or regulatory compliance are involved.

4. Supply Chain and Lead Time Impact Your Schedule

Availability and lead times can vary widely, especially for specialty grades or large quantities. It’s worth asking how material is sourced, what’s kept in stock, and what lead time to expect. Delays in bar stock often cause delays in finished parts.

5. Communication With Your Supplier Makes a Difference

Clear communication about part requirements – especially tolerances, quantities, and intended use – helps avoid surprises. A supplier who understands your needs can flag potential issues early and recommend practical options.

Final Thoughts

Selecting the right bar stock isn’t just about cost – it directly affects how parts run on your machines. Taking the time to get it right upfront can prevent issues later in the process.